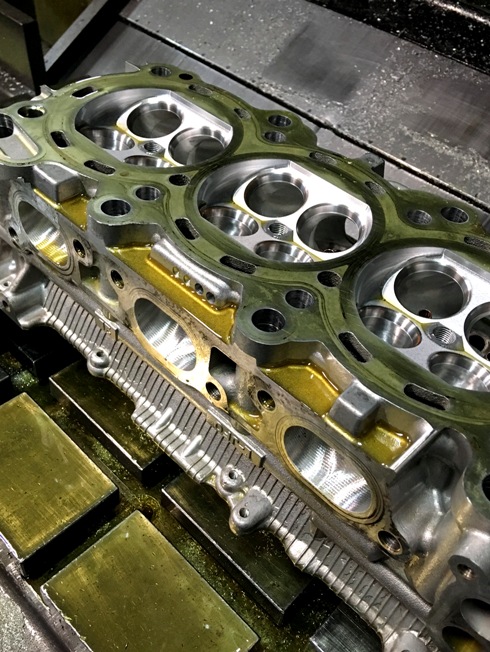

Precise balance correction of a Copen JB-type crankshaft was done today.

A 4 cylinder for a Kei car (Japanese category for small cars) is very special, they are typically 3 cylinder cars.

This crankshaft was produced by casting.

Cast iron cranks are particularly great as they barely bend at all.

We always check to make sure there is as little distortion with the balance as possible.

This time we treated the final surface treatment with manganese phosphate, this reduces sliding resistance and reduces wear.

The image shown is the result of the surface treatment.

After this, we will work on polishing the journal.

![[NAPREC-ナプレック]エンジン・パーツ・チューニング・金属加工・内燃機加工](https://www.naprec.co.jp/docs/wp-content/themes/naprec/images/logo.png)