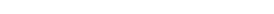

Today, we have a Mitsubishi GTO for processing the lower back as well as piston and crank assembly.

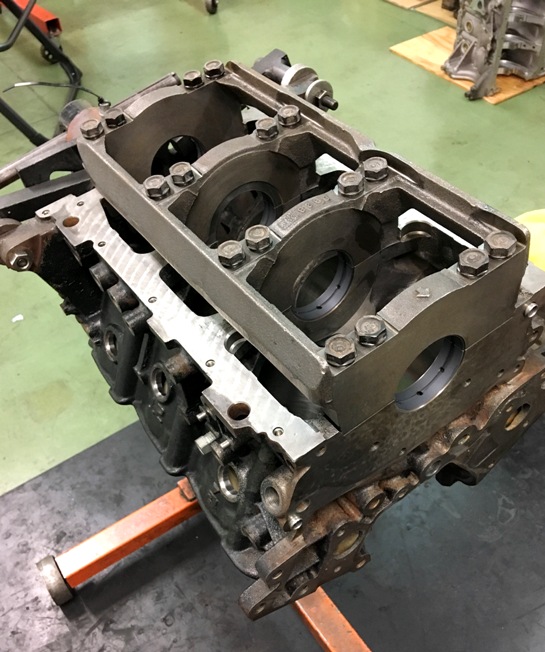

As this is a V6 engine, we implemented dynamic weight balancing with bob weight mounting.

The piston is forged and the connecting rod is an H beam. (H cross section, made overseas, such a thing exists, huh. Also for 6G72.)

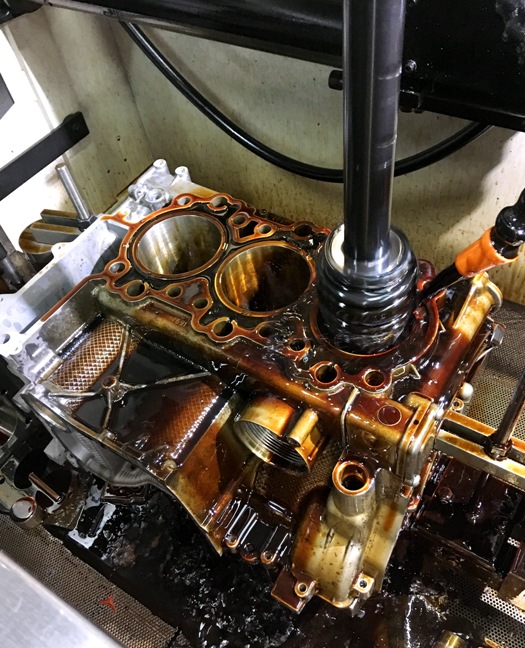

Since this is a 4 main volt block, there’s no doubt it is a DOHC head.

The installation of the oil jet is like an M64 crankcase. (M64 = 964 PORSCHE)

![[NAPREC-ナプレック]エンジン・パーツ・チューニング・金属加工・内燃機加工](https://www.naprec.co.jp/docs/wp-content/themes/naprec/images/logo.png)