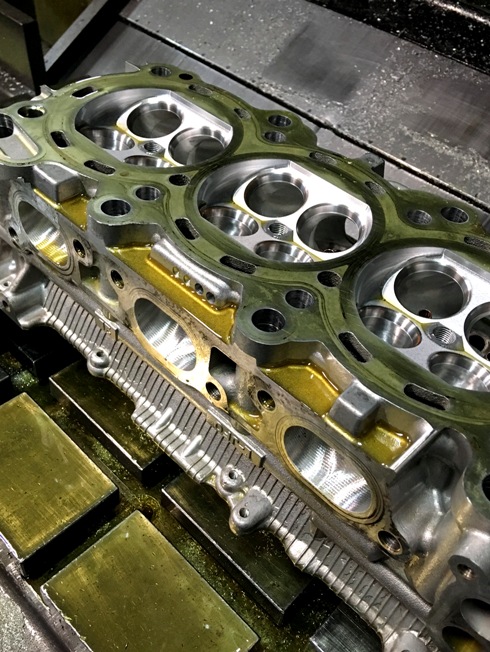

Today we’re working on the inner diameter of the air-cooling cylinders for a Porche2.7. We’re honing to adjust the piston clearance.

At Naprec, we also work on honing Nika Gill cylinders, so we do this type of work on occasion.

We perform the honing by creating a dummy head and crank case and joining them together.

Pretty much all cylinders of Porsche air-cooled engines have nicadil plating treatment with the exception of a few models.

Nicadil plating is a process developed by the company Mare.

The plating has excellent harness and is also a great oil-containing surface. It is an ideal plating option for internal combustion engines and is also able to be processed directly on an aluminum surface.

I would like to alter domestically produced engines to aluminacadylate.

![[NAPREC-ナプレック]エンジン・パーツ・チューニング・金属加工・内燃機加工](https://www.naprec.co.jp/docs/wp-content/themes/naprec/images/logo.png)